Custom Filters vs. Standard Filters: What Manufacturers Want You to Know

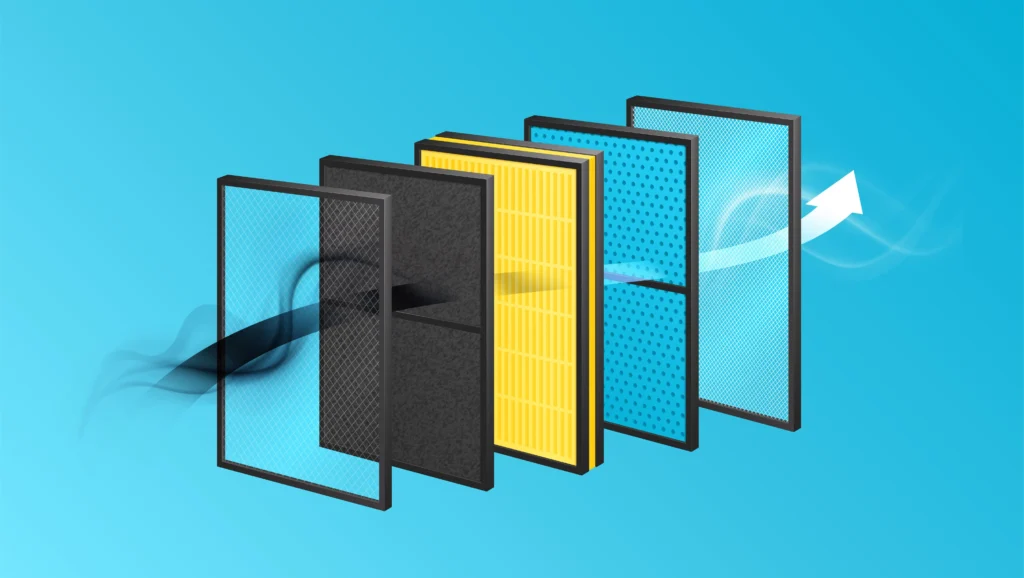

Filters are essential for preserving performance, safety, and efficiency in industrial machinery, vehicle engines, and HVAC systems. Whether at home, at work, or in an industrial setting, filters ensure that the air you breathe is clean and healthful by capturing dust, grime, allergens, pollen, and other particles.

However, numerous companies find it challenging to decide between investing in custom filters or using standard filters. Standard filters are used in different conditions and are available in various sizes. However, custom filters provide more flexibility and efficiency because manufacturers design them to match specific systems or meet particular needs. The decision is crucial and may affect performance, cost, and compliance.

In this blog, we’ll cover everything you need to know, including the basics of each kind and professional opinions from leading filter producers like Anand Filters.

Understanding Standard Filters

Standard filtration products perform incredibly well in general and harsher-duty situations because manufacturers design them to meet various application requirements. They produce these filters in large quantities to cut expenses, following industry standards for longevity, performance, and safety. Most air filter manufacturers and suppliers often sell these filters off the shelf.

Standard filters have numerous applications in electronics, audio processing, and HVAC systems. They are frequently used to eliminate dust, dirt, and other airborne particles from the air in residences, workplaces, and industrial environments.

Pros:

- Standard-size air filters are easily available in both physical stores and online marketplaces. Because they are widely accessible, you won’t have to waste time looking for alternatives.

- Manufacturers produce standard-size filters in large quantities, making them less expensive than custom-made ones.

- Standard air filters are compatible with a wide range of HVAC systems, offering versatile solutions for various setups. Due to their universal dimensions, they function well with most units and don’t require any specific changes or modifications.

Cons:

- Standard filters in HVAC systems with special or customized setups could not fit correctly. Air bypass caused by improper fitting can lower system efficiency and affect air quality.

- Because standard air filters usually cannot collect tiny particles, users may need to replace them more frequently.

What Are Custom Filters?

Manufacturers create customized filters to match your HVAC system and satisfy specific requirements. In contrast to standard filters, which are available in common sizes, customized filters are made to precisely match your system’s measurements. This means they can precisely fit your system and improve performance and efficiency.

Customized filters are sometimes required in locations with unique HVAC systems, such as big commercial buildings, factories, or residences with unconventional ducting.

They are invaluable in settings like hospitals, labs, or places that require filtering specific pollutants like mildew, smoke, or allergens where standard filters might not be adequate.

Pros:

- Custom filters are designed specifically to suit the unique specifications of your HVAC system, ensuring an ideal fit and optimal performance. It enhances energy use and air quality by making the system function more effectively.

- Custom filters offer different materials, sizes, and filtration levels. You can also choose features like high-efficiency filtration or washable designs.

- Manufacturers frequently use high-quality materials to create custom filters, guaranteeing improved performance and longevity. A skilled and expert filter manufacturer can ensure good performance and fit.

Cons:

- Due to their specific manufacturing for your system, custom air filters are typically more expensive than ordinary filters.

- If measurements are not precise, a customized filter may not fit properly, which could destroy its usefulness. Inadequate fit might result in gaps that let allergens and dust enter, decreasing effectiveness.

Key Differences: Custom Filters vs. Standard Filters

Performance & Efficiency: Customized filters typically offer better filtration in terms of performance. Standard filters’ ability to capture particles is shown by their moderate MERV (Minimum Efficiency Reporting Value) rating. Regular filters can capture common dust and allergens, but customized filters made with specialist materials and higher MERV ratings can capture finer particles.

Material Quality & Compatibility: Most HVAC systems are compatible with standard filter sizes. However, a standard filter may not fit properly if your system is unusual in size or shape. In these situations, custom filters frequently employ superior or specialty materials to meet specific industry requirements. It makes customized filters more effective in regions that demand greater air quality standards.

Cost Implications: Standard filters are generally less expensive than customized ones. They are inexpensive and straightforward to change since they are manufactured in large quantities and available in standard sizes. Since air filter manufacturers create customized filters for each customer’s needs, materials and production costs often increase.

Availability & Lead Time: Standard filters are readily available online and at most hardware stores. When you need a replacement, you can easily find one because they are available in conventional sizes. Before being delivered, custom filters must be designed, prototyped, and approved.

Maintenance Considerations: While ordinary filters may need more frequent maintenance because of their general design and materials, custom filters frequently offer longer service lives, minimizing the need for frequent replacements and operating downtime.

What Filter Manufacturers Want You to Know

Prominent filter manufacturers, such as Anand Filters, bring invaluable expertise. They want you to be aware of the following:

- Prior to considering variables like flow rate, pressure, and fluid properties, filter manufacturers assess their customers’ wants by comprehending the particular application and the intended filtration outcomes. Additionally, they consider the customer’s budget, the intended performance, and the filtration solution’s possible lifetime value.

- People often consider standard filters to be “good enough.” However, even little inefficiencies might result in serious operational hazards in sectors such as pharmaceuticals or aircraft.

- Early consultation with filter manufacturers makes a more successful and economical design approach possible. By integrating manufacturers’ knowledge and perspectives early in the process, designers avoid issues.

- Manufacturers advise using standard filters for routine, non-critical applications and going custom when performance, compliance, or system fit are crucial.

When to Choose Custom Filters

- When regular filters are unable to satisfy a process’s unique requirements, such as managing high pressures, temperatures, or flow rates, custom filters ought to be used in complex or hazardous settings.

- Manufacturers make custom filters to fit precisely when machinery has unusual dimensions or operates in extraordinary ways, guaranteeing smooth integration without sacrificing efficiency, design, or airflow.

- When stringent safety or regulatory requirements call for particular performance attributes that ordinary filters cannot provide, custom filters should be selected.

When Standard Filters Are Enough

- Standard filters are frequently advised for general filtration since they are usually adequate for most houses to capture bigger particles like dust, lint, and pollen.

- For projects with limited funds, standard filters provide an affordable option. They are less expensive and offer respectable performance.

- Standard filters can have shorter lead times and are typically less priced. Off-the-shelf standard filters are easily accessible, guaranteeing less downtime.

How to Choose the Right Filter Manufacturer

Your filtering solution may succeed or fail based on your choice of filter manufacturers. What to look for is as follows:

- Above all, you need a filter manufacturer who can provide superior service that their rivals cannot.

- Ask them how long they have been in business before selecting a partner. Seek out essential case studies that illustrate the outcomes they have produced. You should look for a partner who has worked for several decades.

- Your significant other must be thoroughly knowledgeable about filtration technologies. And not only a select group of senior technicians confined by hierarchical tiers. It’s essential for each team member to be fully knowledgeable about the offerings, ensuring that the right information is readily available when required.

- Ask about the quality assurance processes, testing methods, and relevant certifications to ensure standards are met. The best air filter manufacturers will share this openly.

Conclusion

Fit, effectiveness, cost, availability, and applications are the primary areas where standard and custom filters diverge. Standard filters work well for projects with low costs and short turnaround times in environments with regular filtration requirements. However, specialized filters are necessary for high-risk, regulated, or specially designed systems where precision fit, performance, and compliance are crucial.

Evaluating your operating complexity, schedule, and long-term maintenance requirements is crucial for optimal choice. Selecting an expert filter manufacturer such as Anand Filters guarantees you will receive situation-specific technical advice.