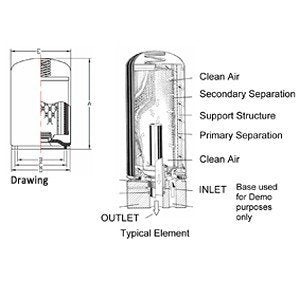

SPIN ON SEPARATOR

The Spin on Air Oil Separator is a built-in separator with an element and a housing of its own. It provides a simple and effective replacement option for air compressor maintenance. It drastically lowers the compressed air’s oil content and returns the filtered oil to the compressor’s air end.

Applications include sliding vane compressors and oil-lubricated screw compressors.

Installation: Perpendicular to the pressure reservoir

3 PPM for residual oil concentration

Maximum operating temperature: 120 °C

Less than 0.2 bar of initial pressure loss

- Low pressure drop and energy conservation

- Top-notch filtration media

- Minimal use of oil

- Dependable and steady

- Compact style

- Extended lifespan

BENEFITS:

High efficiency of separation

All air oil separators use the cutting-edge technology and the best filtration medium available. We work hard to increase separation effectiveness and maintain clean, oil-free compressed air.

Drop in low pressure

Compared to other sources of energy, compressed air is more expensive. The compressor’s energy expenses have a significant role in determining the price of compressed air. High power consumption results from high pressure drop. Throughout their useful lives, spin-on-air oil separators maintain a modest pressure drop.

Housing that resists pressure Under difficult working conditions, random sample tests are routinely conducted to determine the housing of our spin-on oil separator’s pressure resistance limit.

Sealing

Before being delivered to customers, all spin on air oil separators have undergone a test for sealing. Never will we sacrifice dependability. the robustness and security of our goods.

Grounding

Before being distributed to clients, every spin-on air oil separator has undergone an electrical conductivity test. To avoid electrostatic charges, they can be connected to the grounding of compressors via its thread.