How to Maximize Dust Collector Efficiency: Choosing the Right Filter Bags Based on Industry & Application Needs

Understanding the Role of Filter Bags in Dust Collection Systems

Industrial dust collectors play a very essential role in protecting employee safety, ensuring the air is clean, and safeguarding the environment. The effectiveness of a dust collector filter bag depends heavily on how well-tuned and maintained it is.

The primary filtration layer that collects fine particles, increases dust collector efficiency, and safeguards personnel and equipment is industrial filter bags.

The filtering capability and maintenance frequency of your system will depend on several factors, including its design, quality, and filter bag materials.

Types of Dust Collector Filter Bags & Their Applications

Different industries use different types of filter bags, each designed to withstand specific environmental conditions, chemicals, dust loads, and temperatures.

Polyester Filter Bags: Polyester alternatives are dependable for all-purpose industrial dust filtration and are a popular and affordable solution. Industrial filter bags made of polyester are perfect for dry heat settings.

They are resistant to abrasion, chemicals, and dry heat. A facility or industrial plant that generates substantial fine carbon dust can use polyester filters. Because polyester filters degrade quickly, they are not the best choice for facilities with high humidity.

Nomex Filter Bags: Premium filtering systems made from aramid fibers. Baghouse filter bags for industrial use are a standard method for removing dust and particulates from air or other gases, thanks to their long-lasting performance at elevated temperatures.

PTFE Filter Bags: Polytetrafluoroethylene (PTFE) is best known for its extreme chemical and heat resistance; it is the primary raw material used to make PTFE filter bags. PTFE industrial filter bags have been developed to withstand all levels of acid/base pH erosion and to operate continuously at temperatures up to 240 degrees Celsius. It also contributes to a longer service life and increased dust collector efficiency.

Fiberglass Filter Bags: Industries with high acid concentrations are best suited for fiberglass baghouse filter bags. You should avoid using fiberglass filters if your plant generates substantial amounts of hydrofluoric acid, chlorides, cyanides, and bromides.

High-Temperature Filter Bags: High-temperature dust collector filter bags are designed for the most challenging jobs. Ideal for high-heat applications, such as smelting metals and use in power plants and cement kilns, these filter bags can withstand up to 500°F. With exposure to corrosive gases and particles, this type of filter bag is chemically compatible and withstands punishing conditions.

How to Select the Right Filter Bag Based on Industry Needs

Different industries generate different types of dust. If you know your industry’s requirements, you can select industrial filter bags more successfully.

Cement: Dust emissions into the atmosphere are also a problem for cement factories. Dust is produced during the processing of raw materials and when cooling clinker, and a powerful dust removal system is necessary to prevent the danger of airborne particles, whose presence can seriously endanger worker health, reduce machine efficiency, and contaminate the environment. High-efficiency dust collector filter bags will inevitably deliver high-quality air, low dust content, and full compliance.

Metal Fabrication: Metal dust can be harsh and sharp. Durable baghouse filter bags, such as fiberglass or Nomex, support long-term maintenance of the dust collection system by requiring fewer replacements.

Pharmaceuticals: Manufacturing processes require filtration at several stages, so you must select the appropriate filter for each stage. Many industries use bag filters, but the pharmaceutical industry employs them most widely. They are an affordable filtering option that works well for both liquids and dust.

Food Processing: In the food and beverage production sector, bag filters are essential. Filtration systems are critical to the food and beverage processing sectors to ensure the safety and purity of their output. Industrial filter bags made of polyester or PTFE are perfect since they don’t become wet or contaminated.

Woodworking: Numerous industrial woodworking operations process wood using various machinery. They consequently create dust with a range of particle sizes and properties. Because of this, every woodworking dust-collecting system is a different undertaking. It covers cartridge collectors, baghouses, and cyclones. Woodworking applications frequently use various types of dust collectors.

Key Factors That Affect Dust Collector Efficiency

Airflow: The regular airflow captures dust before it can spread. The right industrial filter bags help maintain airflow without clogging.

Micron Rating: Particles can range from very coarse to ultra-fine, depending on the job. Selecting the appropriate micron rating enhances overall industrial dust filtration.

Filter Media: Different filter bag materials are used to satisfy various dust types. High-efficiency filters, such as pleated and PTFE-coated media, offer extended service lives and higher collection rates for many kinds of dust.

Temperature & Moisture: Certain dust collector filter bag types can withstand heat, while others can withstand wetness. Early failure and decreased performance result from mismatched bags.

Tips to Improve Filter Bag Life & Performance

Cleaning Cycles: The cleaning system that maintains your filter bags’ functionality determines how effective they are. Dust accumulation inside baghouse filter bags is avoided by routine cleaning cycles. Dust accumulation results in restricted airflow and elevated differential pressure if it pulses insufficiently. You can maintain the structural integrity of industrial filter bags by finding the ideal balance, often achieved through differential-pressure-based cleaning control.

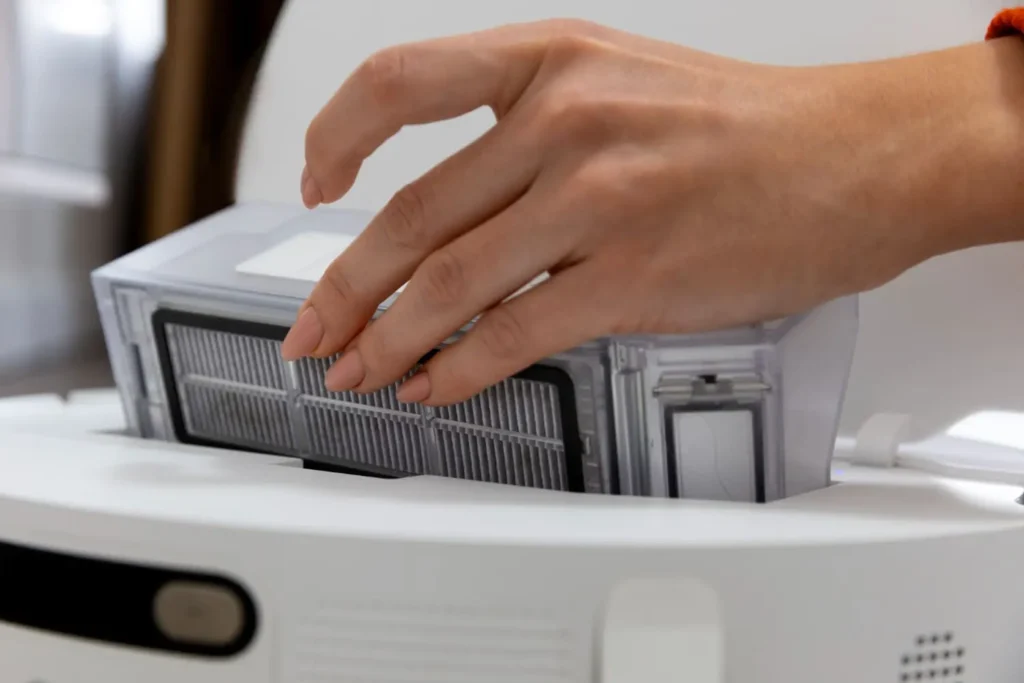

Preventive Maintenance: Preventive maintenance plans and periodic inspections can discover problems before they develop into failures. Look for: physical damage resulting from broken cages or misaligned venturis, an excessive buildup of dust cake, torn bags, and ruptured seams.

Proper Installation: Even the best filter bags will not perform well if installed improperly. Mount the bags under adequate tension, neither too tight, as this puts a strain on the seams, nor too loose, as this promotes abrasion. Shut off dust bypass and air leaks with properly sealed gaskets; select a bag that can be matched to an appropriate cage so that no premature wear will occur from vibration or contact.

Signs Your Filter Bag Needs Replacement

Filter bags are an integral part of your production, to the point that we often overlook their role in the overall process. They keep the product you are producing at a high level of quality, protect everyone’s safety at the plant, and ensure the wheels of manufacturing keep turning. Knowing when to change your filter bags can save you a lot of headaches.

Decreasing Line Efficiency: A slowdown in production clearly indicates that you should change out the bags. Clogged bags can prevent ingredients from reaching their destinations on time, and if that message reaches the operator, it can delay the whole line.

Low Quality Products: Filter bags are key to maintaining the quality of your products. If they are compromised, contaminants may enter the production process, resulting in inferior goods.

Physical Wear: It’s essential to check your filter bags. They can be physically compromised, leading to reduced effectiveness.

Increased Emissions: A lack of filtration can expose your environment & workers to higher levels of emissions. If you have noticed an increase in emissions, check your filter bags.

Conclusion

Industrial applications benefit from selecting the right dust-collection bag filter and properly maintaining it. Your selected filter will help ensure safe, clean air. It protects your equipment and improves the environment. Ongoing maintenance will ensure your dust collection filter performs well throughout its intended life.

You must carefully consider dust-collection requirements, as they vary by industry. Consider consulting an expert to develop a custom solution for your application. With the right filter bag materials and dust collection system maintenance, your plant benefits from reliability, fewer shutdowns, and long-lasting efficiency.

FAQs

1. Why is selecting the right filter bag important for dust collector efficiency?

Choosing the correct filter bag improves filtration performance, reduces pressure drop, enhances airflow, and extends equipment life.

2. What factors should I consider when selecting filter bags for different industries?

Key factors include dust type, temperature, humidity, chemical exposure, airflow requirement, and the specific application environment.

3. Which filter bag materials are best for high-temperature applications?

Materials like Nomex (Aramid), Fiberglass, and PTFE are suitable for industries with continuous high-temperature operations.

4. How do filter bag finishes or coatings improve performance?

Coatings such as PTFE membrane, anti-static finish, or water-repellent treatment help reduce dust buildup, improve cleaning, and handle sticky or fine particles.

5. How often should filter bags be replaced to maintain dust collector efficiency?

Replacement frequency depends on operating hours, dust load, material type, and maintenance practices, but generally every 6–24 months.

6. Can using the wrong filter bag increase operational costs?

Yes, the wrong filter bag can cause high pressure drop, more frequent cleaning cycles, higher energy use, and premature bag failure—leading to increased operational costs.