The Importance of Regularly Replacing Filters in Compressors

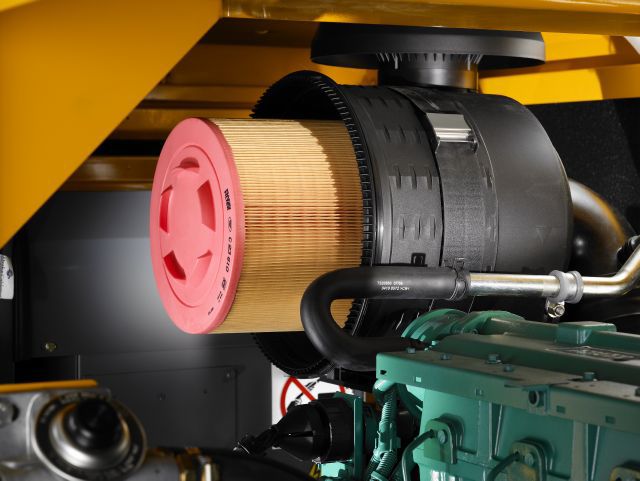

Compressors are critical pieces of equipment that are utilized in a wide range of industrial and commercial Filters. It is one of the most significant and commonly used utilities. They are responsible for managing the pressure and flow of gases by compressing air and other gases. Compressors are employed in a variety of sectors, including automotive, mining, and medicine. It is critical to ensure that the compressed air products in a system are correctly working. Product quality and system lifespan suffer when the required maintenance plan needs to be followed. Filters catch the pollutants and particles that enter the compressor and can become clogged over time. This can result in lower efficiency and potential damage since debris build-up can obstruct gas flow and cause the compressor to overheat. Replacing filters in compressors runs effectively and helps to prevent costly damage.

Why Should Filters in Compressors be replaced?

Replacing filters in compressors must be done regularly to ensure proper and efficient operation. This not only helps to prevent costly damage, but it can also assist in cutting energy expenses and extending the compressor’s life. The filter removes pollutants from the air stream, such as water and oil droplets, mist, dust, and microorganisms. However, as air enters the compressor’s air filter, potentially dangerous and destructive particles become caught between the media fibers. As a result, the filter medium can get clogged over time, resulting in lower differential pressure and increased cost and energy required to run the system.

It is also critical to use a suitable type of compressor filter. Because various compressors require different filters, examining the manufacturer’s requirements is essential to ensure that the proper type is utilized. Because of the extreme circumstances in an industrial compressed air filtration system, it is critical that replacing filters in compressors regularly is essential. A filter element must be able to tolerate the following conditions:

- High temperatures

- Changing air speeds

- Corrosive chemicals

Selecting the Best Filters for Your Compressors

Investing in adequate air filters is the finest things you can do for your industry compressors and your bottom line. Air filters protect your equipment from pollution, water, dust, other particles, and corroding agents. They also clean the air you breathe, preserve the power output of your most vital instruments, and aid in cleanliness. Utilizing the correct filters and replacing filters in compressors at appropriate intervals may save maintenance costs, improve worker safety, and reduce downtime. Get the best air filter for your industry compressors to invest in air quality and clean tools. The Many Air Compressor Filter Types:

a.) High-efficiency particle filters:

High particulate filters are meant to filter out microscopic particles or natural solids such as dirt, dust, pollen, and metallic fragments that can cause tool damage and destroy paint works.

b.) Filters for vapors (or charcoal):

Vapor filters remove vapors, gaseous lubricants, and chemicals from the air compressor. It employs an absorption process to trap contaminants using activated carbon and carbon cloth.

The problem with this filter is that it is designed to absorb gaseous pollutants rather than liquids. Therefore, any fluids that flow through the filter, such as aerosols, will wear it out through saturation.

c.) Filters for coalescing:

One of the most destructive things to your equipment is water. It is a naturally formed liquid during compression and one of the most difficult to filter out continually.

Coalescing filters remove water, oil, aerosols, paint fluid, and other contaminants by collecting them in the filter media and combining them into a pool in the medium. The droplets congregate in a moisture trap that quickly empties the table.

The Benefits of Replacing filters in Compressors regularly

Compressed air is essential in various manufacturing and industrial applications, including pneumatic equipment, petrochemicals, and food processing. Most compressor systems include a filtering system to enhance air circulation and reduce the danger of contamination. To maintain the system running correctly, performing regular maintenance and replacing worn-out components is vital. Every air filter element has a limited service life, and the manufacturer will usually propose a time range during which the filter should be changed to ensure ideal air quality. Advantages of replacing filters in compressors regularly:

a.) Maintain good compressed air quality:

Replacing the air filters regularly creates a safer, cleaner work environment free of impurities that might harm your employees and equipment. Replace the air filters as needed to keep the air filtration system unclogged and operating at optimal performance.

b.) Keep adsorption dryer bedding safe:

In some systems, adding new filters allows the adsorption dryer beds to work at peak efficiency. As a result, they can stay healthy and deliver optimum benefits with less particulate matter in the airflow across them.

c.) Increased production and profit:

Consistent maintenance and changing the air filters will increase efficiency, resulting in higher production and profitability in the organisation.

d.) Reduce operational expenses:

Replacing the air filter parts regularly reduces the possibility of having problems with the entire system, which can result in downtime, costly repairs, and overall inefficiency. In addition, the compressor has to work harder to produce the needed airflow if the air filtering system needs to be appropriately maintained. This strains the compressor, causing it to use more energy, be more prone to damage, and have a shorter lifespan.

Conclusion

Compressors are essential parts of machinery. They keep systems functioning and must be maintained to keep them working correctly. One of the most critical maintenance duties is to replace filters regularly. This helps keep dirt and debris out of the system while keeping the compressor functioning effectively.

Filters can become clogged over time, limiting their efficacy and resulting in lower performance. Replacing filters in compressors ensures that the compressor is operating at peak efficiency, saving energy costs and increasing the compressor’s lifespan.

Read More: How to Choose the Right Compressor for Your Needs