Exploring the Advantages of Screw Compressor with Single-Phase Technology

Screw compressors are now a necessary piece of machinery for effectively supplying compressed air in workshops and businesses. An air compressor that runs on a single-phase electrical power source and compresses air using a screw mechanism is known as a single-phase screw air compressor. This compressor is usually found in smaller applications and settings where a three-phase electrical supply is inaccessible or unnecessary.

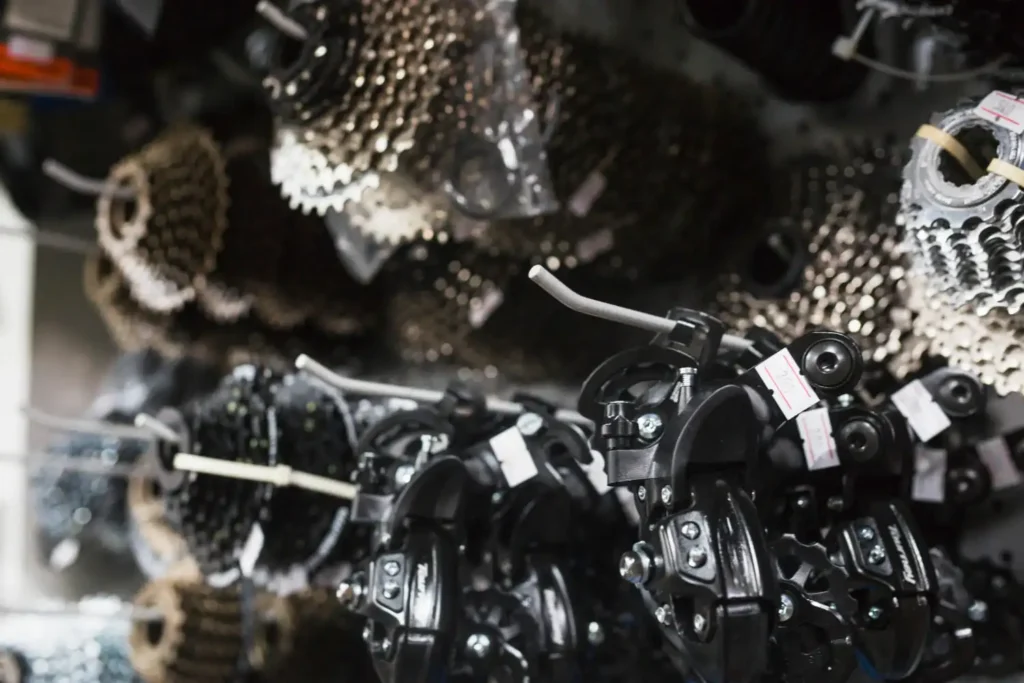

Understanding Screw Compressors

A screw compressor plays an essential role in cooling operations and frequently operates in commercial and industrial refrigeration systems. A screw compressor compresses gas using two helical screws, or rotors, that mesh together.

The fluid is sucked in through the inlet port as the rotors rotate, filling the space between the two lobes. Suction stops when the spaces between the lobes are full of fluid; rotation forces the fluid into a progressively smaller area, which results in compression.

What is Single-Phase Technology?

The screw compression technique, which uses two interlocking helical rotors rotating in opposing directions to trap and compress the air between them, is the basis for how a single-phase screw compressor works. Various commercial, industrial, and personal applications use compressed air because it increases temperature and pressure.

A single-phase electrical supply powers the motor that drives the screw mechanism in a single-phase compressor, commonly found in light-commercial and domestic settings.

Advantages of Screw Compressors with Single-Phase Technology

Energy Efficiency

Single-phase screw compressors have improved compression capabilities, guaranteeing steady and adequate airflow. Its design lowers vibration and mechanical loss while increasing energy efficiency and lowering production costs and energy consumption.

Ease of Installation and Operation

A major benefit of a single-phase compressor is its simplicity of installation. Because they don’t require specialized electrical setups, users with basic infrastructure can use them. Thanks to their user-friendly design, even those with little technical experience can effectively operate them.

Cost-Effectiveness

Single-phase power is more widely used and generally cheaper to install, making a single-phase screw compressor frequently less expensive than its three-phase counterparts. Users can utilize existing single-phase power infrastructure without requiring costly electrical modifications. Furthermore, operating and maintenance expenses are typically lower.

Versatility and Portability

Single-phase screw compressors are incredibly adaptable. Single-phase screw compressors are perfect for locations with limited space because they are typically smaller and more compact than bigger three-phase ones. Because of this flexibility, companies can maximize the space they save and use it for other crucial objectives.

Reliability and Durability

The extended operating life and dependability of screw compressors are well known. They maintain these qualities when using single-phase technology, providing reliable performance even in demanding settings. Using premium parts, like screw compressor oil, guarantees seamless operation and lessens wear and tear, increasing longevity even further.

Applications of Single-Phase Screw Compressors

Various industries, such as [list industries], use single-phase screw compressors:

Automobile Sector: For several uses, including paint spraying, sandblasting, and pneumatic tool operation, single-phase screw compressors with chilled dryers are extensively utilized in the automobile sector.

Food and Beverage Business: The food and beverage business uses compressed air for several processes, including canning, bottling, and packaging. The clean, dry, and oil-free compressed air generated by single-phase screw compressors with chilled dryers is extremely beneficial to the food and beverage sector.

Medical Sector: For several uses, including anesthesia devices, surgical instruments, and breathing equipment, the medical sector needs dependable and clean compressed air. Because they deliver compressed air that is dry, clean, and oil-free, single-phase screw compressors with refrigerated dryers are the ideal choice for the medical sector.

Challenges and Limitations

Screw compressors using single-phase technology have several drawbacks despite their many benefits. Their lower power output compared to three-phase compressors is one of the main issues that could restrict their use for heavy-duty industrial applications. Furthermore, single-phase systems may encounter voltage drops that could impair performance under heavy loads.

Proper maintenance, including routinely replacing screw compressor oil, lessens these problems and ensures smooth performance.

Future of Single-Phase Screw Compressor Technology

Innovative technologies and Internet of Things (IoT) are anticipated to impact the single-phase screw compressor market in the future substantially. Experts project that this advancement will significantly expand the market by enhancing the effectiveness, dependability, and overall operation of screw compressors.

Manufacturers will probably concentrate on making single-phase screw compressors more compact and dependable as the market for portable and adaptable compressors expands. Small enterprises and private users may find single-phase screw compressors even more appealing as a result of these advancements.

Conclusion

An economical, space-efficient, and adaptable solution for smaller businesses in need of compressed air but without a three-phase electrical supply is a single-phase screw compressor. Even though it has many advantages, it’s essential to consider its drawbacks, especially regarding power capacity and efficiency under heavy loads. A single-phase screw compressor might be an excellent option for companies or individuals with more minor air demands because it operates consistently and dependably.