AIR OIL SEPARATORS

The most important component of the compressor filtration system is the air oil separator. Separators of high quality have a long service life.

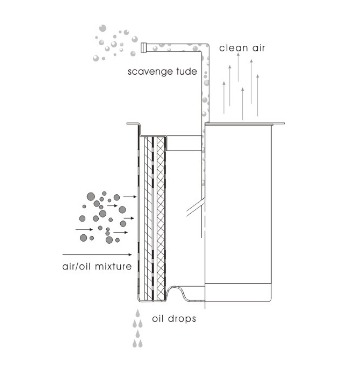

Numerous oil droplets are carried by compressed air from the compressor’s air end. Small oil droplets with a diameter of less than 1 micron will be sustained in the air while larger oil droplets are separated as soon as they approach the tank. Small oil droplets clash and combine to generate larger droplets as they travel through separators with the air circulation. when the size of these oil droplets is unsustainable in the air. They will drop to the separator’s bottom along the fibres of the filtration media and then be transported back to the compressor air end by a scavenge tube.

When constructing each model of air oil separators, each Filter is analysed that may have an impact on the separation process in order to achieve high separation efficiency, minimum pressure drop, dependability, and extended life span.

- Air flow rate and air current velocity are the first of these parameters.

- Working temperature and pressure.

- The pressure tank’s diameter and splash shield’s design.

- The space between the oil level and the separator.

- The pressure tank’s air intake’s diameter and angle.

- Viscosity of oil.

Applications: oil lubricated screw compressors

Installation: inside separator tank

oil content Residual: less than 3 PPM

Operating temperature: up to 120°C

Initial pressure drop: less than 0. 2 bar

- Low pressure drop and energy saving

- High quality filtration media

- Low oil consumption

- Reliable and stable

- Compact design

- Long life span

Air Oil Separators for Air Compressors Filter In India

An air oil separator, also known as an AOS, is a device that separates oil from the air. This type of oil separator is utilized in compressed air systems, screw compressors, engines, and vacuum pumps to remove oil from oil-infused air. Additionally, this helps to prevent oil from entering the intake system, which would otherwise bring about a decrease in your octane level and lead to issues in the future. As an essential component of the compressed air system, these separators play a significant part in ensuring that the intake system operates in a manner that is both effective and secure.

Types of Air Oil Separators Available in India

In many industrial applications, air oil separators are essential for effectively separating oil from compressed air. Numerous varieties of air oil separators are available, each made to fulfill particular industrial requirements. Knowing the differences between the various types is very essential to helping you select the ideal separator for your equipment, increasing longevity and performance.

Coalescing Air Oil Separators

Coalescing air oil separators are made to catch and combine tiny droplets into bigger ones to facilitate the easier separation of oil droplets from the air. In compressed air systems, a coalescing filter eliminates oil droplets and microscopic particles as small as 0.01 microns. A coalescing filter is essential to air preparation because undesired oil can adhere to moving parts and slow down pneumatic cylinders. Coalescing air oil separators are frequently employed in sectors of the economy where preserving high air purity is essential. They provide low oil carryover, safeguarding delicate equipment and cutting down on maintenance expenses.

Centrifugal Air Oil Separators

When centrifugal air oil separators force oil droplets out of the air stream, the spinning motion is used to accomplish this. Centrifugal air separators generate a low-velocity vortex in the middle of the tank. This vortex allows entrained air to emerge from the solution and float to the top of the tank, where it may be readily removed through an air vent or a connection to an expansion tank. These separators are perfect for use in situations where there is a good deal of oil in the air.

Inertial Air Oil Separators

Oil droplets are efficiently removed by inertial air oil separators, which operate on the concept of inertia when the air inside the separator changes direction. Removing moisture and larger particles from the inlet air stream prolongs the life of more effective secondary or final-stage filters. Heavy-duty industrial applications frequently employ them. Because they are easy to use and dependable, inertial air oil separators are a good option for keeping compressed air systems clean.

Air Oil Separators: How it works

Before being discharged into the system, compressed air is cleaned of oil particles using an air separator. The oil-containing compressed air travels through the separator, where it is separated from the air by various processes, including coalescing, centrifugal force, and inertia. A small pipe is connected to the separator, which receives the air after it has passed through a highly tiny filter.

The oil separates from the air because it can’t flow through. The separator gathers the oil by redistributing it into the engine’s supply. Depending on the product, the functionality of an AOS can vary. Some air oil separator suppliers offer models with extra baffles and chambers within the tank to enhance the oil-from-air filtering process. By limiting damage to equipment and preserving optimal operation, this method makes sure that the air stays clear of oil.

Importance of Using Genuine Air Oil Separator:

Industrial machinery safety and efficiency depend on using genuine air oil separators. An air oil separator is a vital component of the separation procedure. It guarantees that the outlet receives only air and not any oil. Therefore, the air separator must be changed periodically. It is important to use an authentic separator with caution. Trusted air oil separator manufacturers in India provide high-quality, reliable products that ensure optimal performance and safety for your machinery.

Safety hazard:

Using fake air oil separators can put your safety in danger. Ineffective separators have the potential to contaminate the air system with oil by failing to remove oil properly. Using parts of poor quality will cause significant damage and increase the risk of a fire incident. An inadequate earthing process can cause a non-genuine air oil separator to collapse. It might blow up the entire equipment. It presents a serious risk to employees and the workplace, possibly leading to equipment failure or even accidents.

Reduced machine performance:

Air oil separators that are not authentic can substantially hinder the equipment’s functioning. The motor is subjected to an increased load due to the increased pressure drop. When there is insufficient separation, the quality of the air deteriorates, performance decreases, and the components further downstream are damaged.

High power consumption:

Utilizing air oil separators of poor quality can increase the amount of electricity consumed. Separators that could be more efficient may require the air compressor to work more to attain the necessary level of air quality. The dense nature of the filtration material produces an additional pressure drop, which in turn increases the amount of power consumed.

Air oil separators from ANAND-FILTER: Benefits at a glance

Anand Filter makes premium air oil separators that fit the requirements of different industrial applications. Their separators provide effective oil removal, improving the lifespan and performance of the equipment. To get high separation efficiency, minimal pressure drop, dependability, and prolonged life term, every filter that could affect the separation process is examined before building a model of an air oil separator. Anand Filter is the leading air oil separator supplier. The advantages are increased energy efficiency, lower maintenance costs, and better air quality. Anand Filter, India’s top air oil separator manufacturer, guarantees dependable and efficient solutions for your air separation requirements.

FAQ (Frequently Asked Questions)

Using an air oil separator to remove oil particles from compressed air guarantees that the air is clean and free of oil at all times. This procedure safeguards the equipment, improves its performance, and lowers the costs associated with its upkeep.

The oil separator performs just as its name suggests: to protect the system’s components and the equipment at the end of the line. It is a filter contained within an air compressor system. It separates oil from compressed air.

To accomplish its function, an air oil separator generates a centrifugal force that successfully separates the leftover oil from the compressed air. A tangential intake allows compressed air to enter the separator, which causes the separator to spin at a high rate.

An air separator removes oil from compressed air. The air-oil mixture enters, oil droplets coalesce and separate, and clean air exits. Regular filter maintenance is essential for efficiency.

An oil separator is a specialized tool to accomplish one crucial task: separating water from oil. This seemingly straightforward task is vital for numerous sectors. By keeping oil and water apart, an oil separator aids in the correct handling of both substances.