How to Choose the Right Screw Compressor Oil for Your Needs

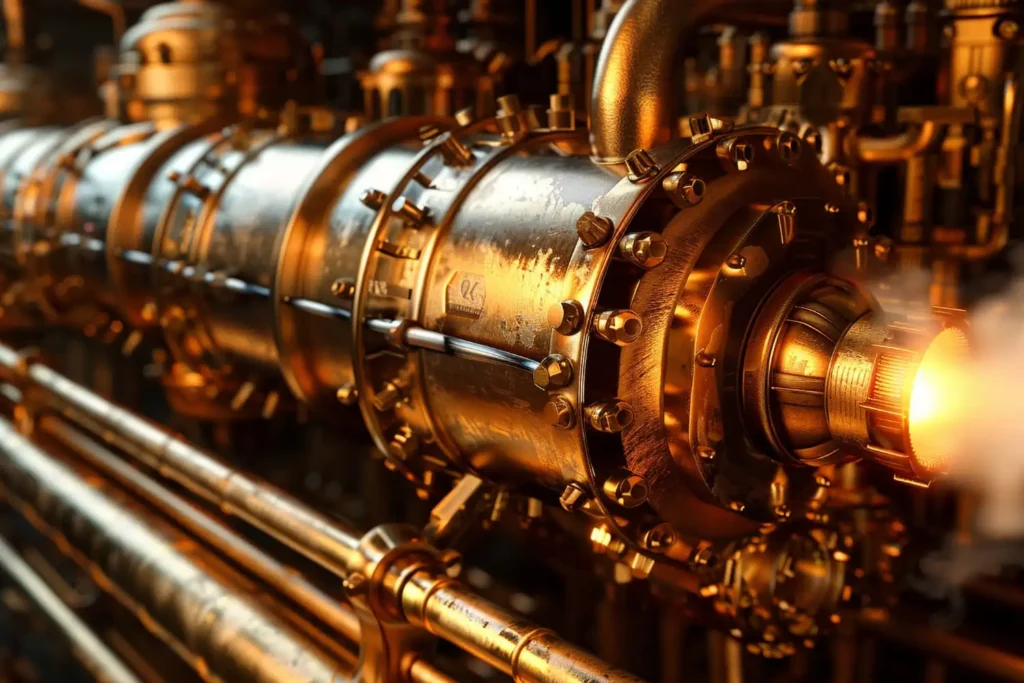

Screw compressors are vital parts of many industrial processes because they supply the compressed air required by numerous devices and systems. However, choosing the proper screw compressor oil is essential to a screw compressor’s long-term performance and efficiency. These fluids are necessary to screw machines for heat transmission, water removal, sealing, bearing lubrication, and system cleaning.

Since they operate in a harsh environment, these fluids must perform well under conditions typically considered excruciating in other lubricant applications. Knowing the fundamentals of the oil system can help us recognize the value of the lubricant and provide some guidance when problems appear. A specialized lubricant created to satisfy the particular needs of rotary screw compressors is called compressor’s screw oil. Unlike other oils, this one must function under high temperatures and pressures to keep the compressor running correctly.

Key Factors to Consider When Choosing Compressor Oil

Compressor Type and Specifications: The oil has different requirements for different compressor types. Rotary screw compressors require an oil that will hold up to high-pressure operation and long run times in a harsh environment. Some compressors have specific requirements around viscosity or additives.

Operating Conditions: Your compressor’s operating conditions significantly influence oil selection. If your compressor operates in extreme heat or cold, you’ll need oil that can tolerate these conditions without degrading. Low temperatures may cause the oil to thicken, decreasing its usefulness, while high temperatures may cause the oil to thin down and lose its lubricating qualities.

Lubrication Requirements: Proper lubrication is crucial to preventing internal compressor component wear and tear. The compressor’s numerous working parts are lubricated by oil. Lubrication helps reduce friction between moving parts, postponing their eventual failure.

Viscosity: The right viscosity of oil must be used to maintain adequate lubrication between the compressor’s working elements. Viscosity affects how the oil behaves at different temperatures. In warmer climates, oils with a higher viscosity work better, whereas those with a lower viscosity work better in colder temperatures. Incorrect viscosity minimizes wear on compressor parts and friction through proper lubrication.

Performance Attributes to Look for in Compressor Oil

Oxidation Resistance: Oxidation can build up varnish, sludge, and other dangerous deposits. Antioxidants slow down the oxidation process, prolonging the life of the oil and enhancing compressor performance. Premium oils resist oxidation and can run compressors longer without deteriorating performance.

Thermal Stability: Oil’s ability to remain operational under high temperatures is known as thermal stability. Oil that does not have the proper thermal stability can break down quickly when under continuous high temperatures as the compressor runs in the system, putting the compressor at risk. If your system is under high to extreme temperatures, consider the manufacturers’ lubricants that have even higher heat stability.

Corrosion Prevention: Compressors are frequently exposed to impurities and moisture, which can lead to internal corrosion. Oil with corrosion-preventive additives keeps the compressor’s metal parts from rusting and corrosion, prolonging their lifespan and ensuring optimal performance.

Anti-wear Additives: Premium screw compressor oils frequently have anti-wear chemicals in them that coat metal surfaces in a protective layer. By lowering friction and wear on the compressor’s working elements, these additives prolong the component’s service life.

Oil Compatibility with Compressors

OEM Recommendations: You should always choose any oil for the screw compressor according to the guidelines of the Original Equipment Manufacturer (OEM). After testing the design of the compressor you call forward, the manufacturer proposes the best oils. Oil not conforming to OEM requirements may invalidate the warranty and create operational problems.

Compatibility with Seals and Materials: Seals, gaskets, and other non-metal parts of the compressor can fail if the wrong oil is used. Ensure the oil chosen is compatible with all internal components.Environmental Impact of Screw Compressor Oils

Eco-friendly Oils: Numerous sectors are switching to environmentally friendly screw compressor oils as concerns about sustainability increase. For best results, screw compressors require specific kinds of synthetic lubricant. These lubricating fluids, however, have the potential to harm surrounding streams and groundwater when leaks happen. Use premium, environmentally friendly lubricants, and fluids whenever possible. The formulation of these low-emission, biodegradable oils is to reduce environmental harm.

Disposal and Recycling: You cannot emphasize enough the significance of recycling and disposal when trying to create a more environmentally friendly environment. This technique can be used for screw compressor oil to help the environment. For the environment’s sake, used compressor oil must be disposed of properly. Many oils can be recycled, minimizing waste and its adverse environmental effects.

Cost vs. Performance: Striking the Right Balance

Initial Cost vs. Long-term Savings: Although cheaper oils may appear to be a better deal at first, they are often more expensive in the long run. Low-quality oils result in more frequent oil changes, engine wear, and increased fuel consumption. High-quality oil will increase efficiency; the up-front cost can pay for itself over the long term.

Energy Efficiency: The right oil can make a screw compressor consume less energy. The more perfect the lubricant in question, the lower the level of friction among the moving components; this results in achieving a higher level of energy efficiency for the compressor.

Signs That It’s Time to Change Your Compressor Oil

Decreased Performance: It might be time for an oil change if the efficiency of your compressor begins to decline. Degradation of the oil can raise friction, which makes the system work harder and use more energy.

Excessive Heat or Noise: Extreme heat and strange noises coming from your screw compressor may be signs that the oil has lost its lubricating qualities, which could lead to significant damage or even total shutdowns. You must maintain your system to prevent additional harm if it is constantly overheating.

Visual Oil Inspection: Routinely checking the oil can identify problems before they worsen. It must be changed if the oil seems dense, murky, or contains sludge.

Conclusion

You need to carefully consider several aspects when selecting the proper screw oil, such as the manufacturer’s reputation and dependability, energy efficiency, noise level, capacity and pressure requirements, and maintenance and serviceability. You may choose the screw compressor oil that best meets your unique requirements and guarantees peak performance and long-term cost savings for your company by weighing these critical factors. Anand Filters designs a variety of screw compressor oils to fit various compressors and operating situations, providing top-quality oils that meet all these needs.