Ultra-High Efficiency & New Media in HEPA Filters (Beyond H13/H14): Trends & Challenges 2025

Indoor air quality has become a very significant issue in both residential and commercial environments. High-Efficiency Particulate Air Filters (HEPA) are high-grade air filtration equipment recognized for their practical ability to capture numerous particulates present in the air, providing benefits that contribute to improved air quality.

Facilities often deploy HEPA filters in sensitive environments to minimize the presence of airborne pollutants. Not all HEPA filters are created equal. The pharmaceutical industry, cleanrooms, healthcare environments, semiconductor manufacturers, and upscale HVAC settings frequently utilize two dominant classifications of HEPA filters, H13 and H14.

The demand for ultra-high-efficiency HEPA filters is increasing due to worsening air quality, growing regulations, and heightened public awareness of health-related issues.

HEPA filter manufacturers are now developing new media and HEPA filter designs to enhance filter effectiveness, while also exploring energy usage, sustainability, and maintenance.

What’s Driving the Demand for Ultra-High Efficiency HEPA Filters?

The popularity of ultra-high-efficiency HEPA filters is increasing globally due to several factors.

Various contaminants, including dust, pollen, pet dander, mold spores, and any volatile organic compounds (VOCs), can negatively impact indoor air quality. Additionally, airborne microorganisms, viruses, and other harmful particles can spread and pose the threat to the health of building occupants.

Adjacent to a pandemic setting, which is flanked by high-risk and tedious chronic conditions, many people know that good air filtration (with HEPA filters specifically) can significantly reduce harmful pollutants for all, and every maintained space can be a little bit healthier and a little bit more comfortable for all.

The COVID-19 pandemic raised awareness of indoor air quality issues even further. Indoor air filtration has been recognized as necessary by the healthcare, hospitality, office, and residential sectors, helping to reduce transmission of viruses and airborne illnesses.

As the demand for air cleaner technologies has increased, there is a need to understand how these filters work and recognize their levels of efficiency, enabling informed decisions. This regulatory push encourages HEPA filter manufacturers to create and develop advanced filters with price and energy efficiencies that exceed those of standard H13/H14-rated filters.

Innovations in HEPA Filter Manufacturing

The air filtration industry has seen significant advancements and innovation in recent years, driven by the demand for hygienic environments and heightened interest in indoor air quality.

HEPA filters have long been considered the standard for air filters, with the capacity to remove 99.97% of particles at a 0.3 microns or larger in size. New developments in HEPA filtration technology aim to produce a quieter, more energy-efficient air purifier while maintaining maximum airflow and overall filtration efficiency.

HEPA filter manufacturers are investing in research and development to produce ultrahigh-efficiency media that collect particles 0.3 microns in size or larger, utilizing multilayer designs, electrostatic charge, and/or nanofibers. These air filters can achieve similar capture efficiencies without increasing pressure drop.

Electrostatic precipitators are devices that use electric charge to capture particles in the air. Recent advancements in electrostatic precipitation technologies that are being developed are looking to create designs for electrostatic precipitators that will ensure better efficiencies, decreased ozone generation, and improved reliability with new electrode materials and designs.

Air filtration continues to evolve with the increased use of nanotechnology, including nanofibers and nanoparticles for enhanced flow and filtration performance, with lower resistant loss. Nanotechnology also provides ultrafine filtration capacities that capture submicron particles which conventional filtration may not be able to provide.

Smart filters enable users to manage and monitor indoor air quality remotely using a smartphone app. Some innovative air scrubber models feature sensors that determine real-time contaminants and automatically adjust filtration parameters for optimal filtration quality.

Role of HEPA Filter Manufacturers in India & Globally

India is a emerging as a key hub for filter production, as the world experiences an increasing demand for HEPA filtration in the air. Among the diverse industries that HEPA filter manufacturers in India service, healthcare, pharmaceuticals, automotive, electronics, and home air filtration represent some of the common sectors.

Experts anticipate a rise in demand for HEPA filters in India. Indoor & outdoor air pollution represent a significant issue in many urban, industrial, and rural areas in India. The growing awareness of health risks associated with airborne contaminants (i.e., pollen, dander, and particulate matter) has prompted consumers, businesses, and institutions to take HEPA filters as a practical option.

There is a high demand for high-grade cabin air filters, particularly in the automotive sector. Automobile filter manufacturers in India are incorporating HEPA technology into vehicles to enhance cabin air quality and reduce ambient air pollution in urban areas. At the same time, the growing electric vehicle market is providing OEMs the opportunity to promote energy-efficient/equal filters that offer better performance in a smaller package, without compromising on modern design language.

Challenges in Ultra-High Efficiency HEPA Filters

Ultra-high-efficiency HEPA filters, although very effective, do present additional challenges. When manufacturers can offer a suitable solution for a range of applications, they must also consider the three key factors of efficiency, cost, and energy efficiency.

- Generally, ultra-high-efficiency HEPA filters are more expensive than standard H13/H14 filters due to the specialized media and complexity of the manufacturing process.

- The pressure drop across the filter is a primary challenge of high-efficiency filters and can increase energy demand in HVAC systems.

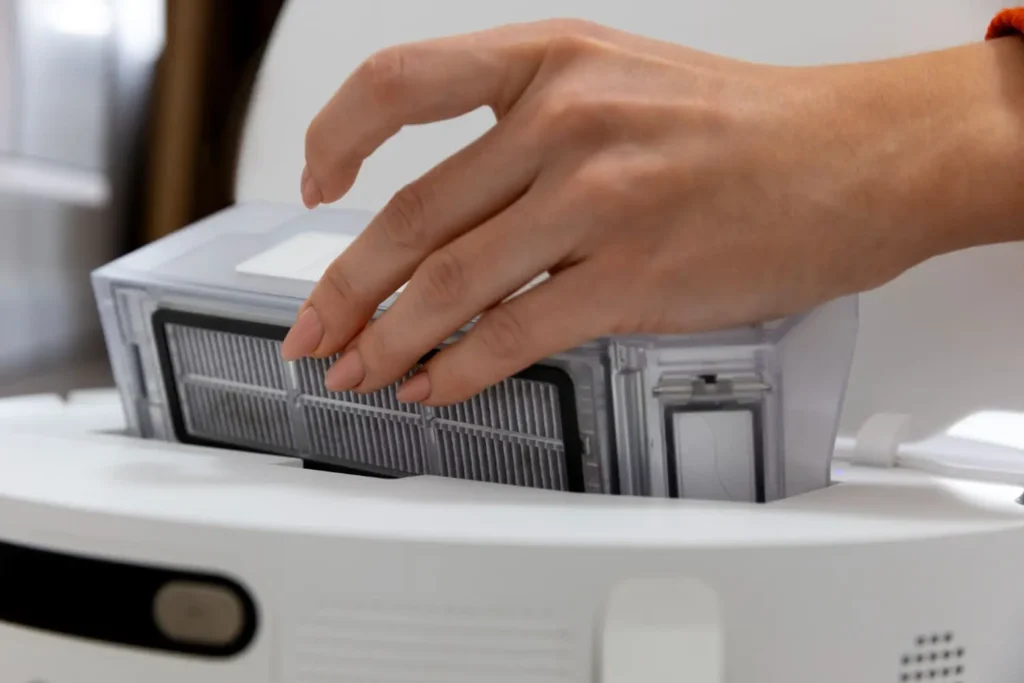

- Users must perform regular maintenance on ultra-high efficiency HEPA filters to keep them effective and replace them systematically and appropriately. If a filter is blocked or defective, there will be a significant fall-off of airflow, energy demand, and particle removal rates.

Future Outlook

Innovation, strategic industry investment, and global economic recovery are driving accelerated growth in the HEPA filter sector. To realize long-term shareholder value, players in the HEPA filter market are shifting their focus away from traditional service priorities to prioritize innovation, digital transformation, and ecosystem relationships and practices.

One of the key drivers of HEPA filter market will be an increasing number of companies utilizing advanced technologies, like blockchain, AI, IoT, and big data, in their offerings.

The use of the advanced technologies will enable HEPA filter manufacturers to develop and provide more customer-centric solutions, leading to improved decision-making and operational efficiencies. Similarly, predictive data in the optimization of supply chains with automation will increase productivity.

Automobile filter manufacturers in India that increase their presence, allowing more people to install HEPA filters, will also help expand the market in the future. The manufacturers will continue to invest in the R&D for filters that meet global standards, as well as those that are economical and energy-conscious.

Conclusion

High-efficiency particulate air (HEPA) filters are among the most effective air-cleaning devices for positively impacting indoor air quality and respiratory health, due to their ability to remove the wide range of air contaminants.

As the demand for advanced filter technology increases in cleanrooms, vehicles, hospitals, buildings, and homes, it is essential to find a reliable, durable, and practical HEPA Filter manufacturer that meets the applicable regulatory performance specifications for your specific application.

By working with a reliable manufacturer, businesses and individuals will benefit from improved air quality, enhanced health safety, and an energy-efficient operation.